winjer

Member

Intel 20A Node Cancelled for Foundry Customers, "Arrow Lake" Mainly Manufactured Externally

Intel has announced the cancellation of its 20A node for Foundry customers, as well as shifting majority of Arrow Lake production to external foundries. The tech giant will instead focus its resources on the more advanced 18A node while relying on external partners for Arrow Lake production...

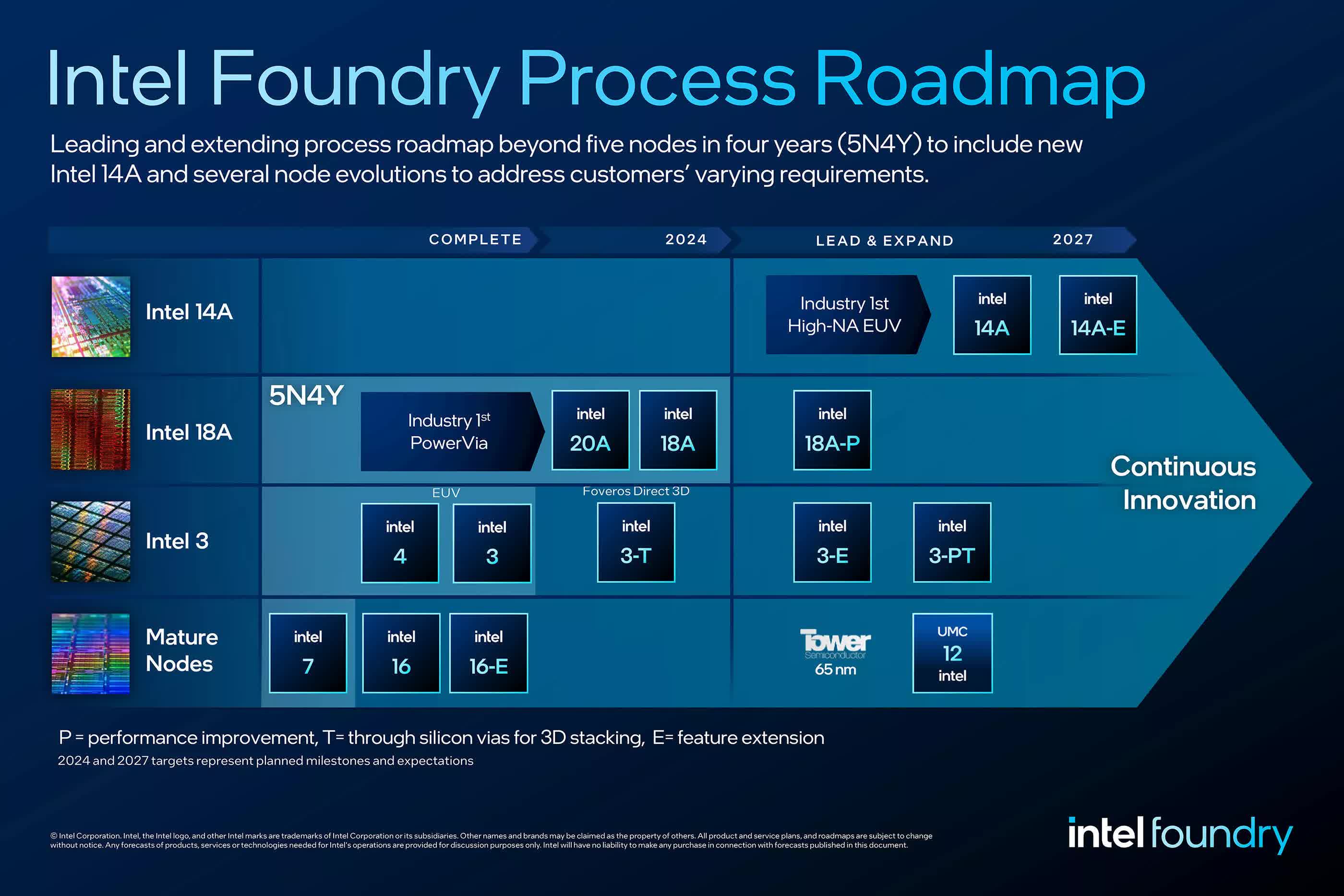

Intel has announced the cancellation of its 20A node for Foundry customers, as well as shifting majority of Arrow Lake production to external foundries. The tech giant will instead focus its resources on the more advanced 18A node while relying on external partners for Arrow Lake production, likely tapping TSMC or Samsung for their 2 nm nodes. The decision follows Intel's successful release of the 18A Process Design Kit (PDK) 1.0 in July, which garnered positive feedback from the ecosystem, according to the company. Intel reports that the 18A node is already operational, booting operating systems and yielding well, keeping the company on track for a 2025 launch. This early success has enabled Intel to reallocate engineering resources from 20A to 18A sooner than anticipated. As a result, the "Arrow Lake processor family will be built primarily using external partners and packaged by Intel Foundry".

The 20A node, while now cancelled for Arrow Lake, has played a crucial role in Intel's journey towards 18A. It served as a testbed for new techniques, materials, and transistor architectures essential for advancing Moore's Law. The 20A node successfully integrated both RibbonFET gate-all-around transistor architecture and PowerVia backside power delivery for the first time, providing valuable insights that directly informed the development of 18A. Intel's decision to focus on 18A is also driven by economic factors. With the current 18A defect density already at D0 <0.40, the company sees an opportunity to optimize its engineering investments by transitioning now. However, challenges remain, as evidenced by recent reports of Broadcom's disappointment in the 18A node. Despite these hurdles, Intel remains optimistic about the future of its foundry services and the potential of its advanced manufacturing processes. The coming months will be crucial as the company works to demonstrate the capabilities of its 18A node and secure more partners for its foundry business.

Broadcom's Testing of Intel 18A Node Signals Disappointment, Still Not Ready for High-Volume Production

According to a recent Reuters report, Intel's 18A node doesn't seem to be production-ready. As the sources indicate, Broadcom has been reportedly testing Intel's 18A node on its internal company designs, which include an extensive range of products from AI accelerators to networking switches...

According to a recent Reuters report, Intel's 18A node doesn't seem to be production-ready. As the sources indicate, Broadcom has been reportedly testing Intel's 18A node on its internal company designs, which include an extensive range of products from AI accelerators to networking switches. However, as Broadcom received the initial production run from Intel, the 18A node seems to be in a worse state than initially expected. After testing the wafers and powering them on, Broadcom reportedly concluded that the 18A process is not yet ready for high-volume production. With Broadcom's comments reflecting high-volume production, it signals that the 18A node is not producing a decent yield that would satisfy external customers.

While this is not a good sign of Intel's Fundry contract business development, it shows that the node is presumably in a good state in terms of power/performance. Intel's CEO Pat Gelsinger confirmed that 18A is now at 0.4 d0 defect density, and it is now a "healthy process." However, alternatives exist at TSMC, which proves to be a very challenging competitor to take on, as its N7 and N5 nodes had a defect density of 0.33 during development and 0.1 defect density during high-volume production. This leads to better yields and lower costs for the contracting party, resulting in higher profits. Ultimately, it is up to Intel to improve its production process further to satisfy customers. Gelsinger wants to see Intel Foundry as "manufacturing ready" by the end of the year, and we can see the first designs in 2025 reach volume production. There are still a few more months to improve the node, and we expect to see changes implemented by the end of the year.

Report: Intel Could Spin Out Foundry Business or Cancel Some Expansion Plans to Control Losses

According to a recent report from Bloomberg, Intel is in talks with investment banks about a possible spin-out of its foundry business, as well as scraping some existing expansion plans to cut losses. As the report highlights, sources close to Intel noted that the company is exploring various...

On a positive note, if Arrow Lake is using TSMC for it's production, then power usage will be much lower, and probably there won't be issues with degradation of Intel CPUs.